How to Prepare for the Big Maintenance Event – Engine Overhauls and Inspections

Part two of a three-Part Series

Most people are in the habit of scanning or reading just the first page of a proposal. This is dangerous habit when it comes to complex maintenance proposals. By not making the effort to thoroughly read the entire proposal, you might assume the number at the bottom of the page is the true, out-the-door cost for the work scope. This number could get passed on to the owner and become the only number that he or she remembers about the big event that is coming due. Many of you can imagine or may have experienced what happens when that estimated number and the actual costs differ by 20 percent or more.ast month in part one of this three-part series, we discussed the steps you need to take prior to soliciting an estimate for your major event. In this article, we will cover what should happen once you receive the estimates. There are endless details to cover in order to be prepared for a major inspection or engine overhaul. Missing one item or not fully understanding all the elements or the intent of a proposal can add delays and unexpected costs.

Types of Estimates

First, understanding the different types of proposals that are currently used is very important. The most common type of proposal issued today is referred to as an “estimate.”

The first type of estimate is the time and material (T&M) version. T&M includes all the labor hours based on the published hourly shop rate and the parts that are required to perform the task. The time (T) portion of the number is not rounded or all inclusive. If the full work scope of induction includes tear down, inspection, repairs, service bulletins, reassembly and test cell certification, and requires 2,000 labor hours @ $110 USD shop rate, then $220,000 would be charged for the labor. Materials such as parts, kits and consumables would be additional line items on the invoice. The combined totals for (T) and (M) comprise the out-the-door T&M charge (excluding taxes). Generally, this is straight forward. Later in this article, I will discuss the relevant tax implications.

The second type of estimate is a flat rate (FR). This type of estimate is a hybrid that combines flat rate and T&M. The flat rate charge covers labor and basic parts and consumable kits required to perform the work scope. The charge on the labor is all inclusive and not negotiable. It usually includes teardown, inspection and repair on common parts, accessory overhaul, reassembly and test cell. The kits include all the O-rings, hardware, shims, retainers and seals. Occasionally, other parts that might be included are some of the common items that usually fall out of inspection tolerance, such as turbine nozzle segments, guide vanes, igniter plugs, probes, sensors, tubes and air and carbon seals. As a rule, expensive parts or life-limited parts such as compressor and turbine disc blades, combustion cans and liners, shafts, bearings, engine cases and frames are excluded from this FR estimate. Service bulletins usually have a separate charge for labor and parts. As with any estimate, you need to review carefully to understand what is included in and excluded from the flat rate. Sometimes the facility’s quote will cover combustion cans or nozzle guide vanes, but they won’t state how many. They may also reference receiving an engine with normal expected wear so you need to ask the question, “What is a normal?” The facility may cover three out of 10 total installed nozzle guide vanes. Anything over three is going to be an additional charge at the T&M rate and over and above the flat rate. Don’t be shy about asking questions — it could save you an unpleasant surprise of thousands of dollars.

The third type of estimate is a not to exceed (NTE). The NTE usually combines flat rate and T&M but has a maximum ceiling price that is not to be exceeded. It is inclusive of all the same flat rate terms and conditions, but no matter how many parts are unserviceable or scrapped out, the cost will not be exceeded. Sometimes there are exclusions, so read as carefully as you would a maintenance manual and make sure you understand.

The final type of proposal is the firm fixed quote. These quotes are usually firm, fixed numbers that include all labor and parts. Beware of this term, though, because it can be misused in a proposal. The fixed quote work scope process includes teardown, inspection, rework, build and test, with all the parts — no exclusions. It sounds attractive because it gives you a guaranteed out-the-door number with no risk. The down side is that the price is usually high and means that you will pay that firm price, even if the actual labor and parts are less.

Exclusions

With all the aforementioned types of proposals, there are variations and exclusions that can change the intent and terms of the proposal that could mean an additional charge, over and above the estimate. Examples of common exclusions are foreign object damage (FOD), corrosion, thermal distress, over temp or impact damage. In some cases, the exclusions are not spelled out. They are buried within a paragraph that will state something like “…assuming the engine arrives with normal expected wear and tear.” So, as mentioned above, you need to ask “What is normal?” When you see a statement like that, get the details of what is expected normal wear and tear in writing. Don’t assume — it could become a big, ugly surprise.

Turn times will also have exclusions for delays not caused by the MRO facility, such as an OEM or vendor parts shortage or special process contracted outside the facility’s control.

I have seen some owners contact a lawyer to review each proposal, line by line, but I don’t believe this level of review is necessary (unless it makes the owner more comfortable with the process). I suggest making notes and circling any areas that need clarification.

Reach out to the appropriate sales engineer and request explanation of any confusing exclusions and, if need be, request that a change be made to the proposal in writing, just in case you or someone from the facility is no longer involved when the event actually occurs.

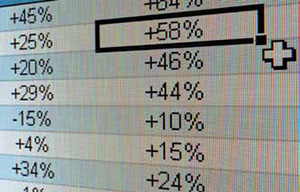

Comparing Proposals – Building a Spreadsheet

Competing proposals are never structured the same way. All the facilities have some type of variance that makes it difficult to compare them apples to apples. It will take a lot of work to show comparisons between the proposals, and you will need to build a spreadsheet that lists all the line items to help you explain to the owner the variations in the costs, incentives and turn time. To make it easy, we will share with you the spreadsheet that our JSSI technical team uses for comparing facilities. Send an email to technicalservices@jetsupport.com to get your copy. Now you can start to load the spreadsheet and move onto the next step.

The most difficult sections of the spreadsheet will be the service bulletins and the parts estimate sections. In Part One of this series, I mentioned that some MRO facilities have their own recommended build standard for service bulletins so they might not follow the same category as the OEM. For example, facility No. 1 might want you to incorporate SB 72-1001 that is listed as an OEM optional service bulletin because they believe it adds value to the engine reliability. Facilities No. 2 and No. 3 may not include it in their proposals because it is listed as an optional service bulletin by the OEM and they don’t believe it adds or improves reliability. This can also hold true for mandatory and recommended bulletins, so you need to be well-versed on all the applicable service bulletins and decide whether or not you want them installed. You can add or remove any service bulletin from the proposal — just be cautious on how it will affect the warranty or performance of the engine. Then request a revised proposal, including only the service bulletins that you want.

Rework and repair is another area of importance, so make sure you understand how much of the repair and rework is covered in a flat rate proposal. If it’s not included, request the facility provide an estimated cost to add in that column. Obtain the shop labor rate because it’s not always the same and depends on the vendor and repair item.

A new trend over the last decade that has grown in popularity since the 2008 downturn is that OEM engineering groups are now charging for their services. When a part needs rework and the repair is not in any of the overhaul manuals or requires an engineering order to be developed, there is a one-time charge per each repair scheme or engineering order. Sometimes the MRO facility designed the repair but the OEM has structured it to where each repair must be approved by them. This single issue can result in added cost anywhere from $3,000 or as high as $30,000 USD. I know this because I have paid for it on several occasions.

The parts section is where you will find the largest inconsistency. To be as accurate as possible, you will need to get the details from each facility. If you don’t have the time to dig into the actual scrap rates on individual parts, I suggest that you ask each facility for invoices for the most expensive and least expensive events for your model and similar engine total time. Also, ask for the mean number if it has not been provided. Most facilities are willing to provide this information. Then, simply compare what each facility provided in parts attrition to determine what is reasonable. Next, I would contact the facility with the highest cost for both their mean and highest invoice total. Inquire as to what the most expensive parts in that cost were so you can have a better understanding of what failed inspection. The cost driver might not be the volume of parts but it could be a single part that is very expensive. Also, in the spreadsheet, segregate the life-limited components out, as those items should not be part of the parts attrition number. Depending on how the flight crew operates the aircraft, you might want to add something into your spreadsheet over and above the mean number. The goal here is to build an accurate spreadsheet, not to find the least expensive estimate. If it seems reasonable, then trust your instincts and add it to the spreadsheet.

Make sure you load each section of the spreadsheet. Include segmented labor, rework, parts, service bulletins, test cell engine change and turn-time incentives. When you run across items that were quoted on one proposal and not quoted on another, add the line item to the spreadsheet and get the facility to give you a number or explanation as to why it’s not in the proposal. Every line item should have an estimate or a reason why it’s missing. This process could take two weeks or more, so be prepared to follow up and make calls.

Once you finish the spreadsheet, the negotiations start with each facility. There are many things that you can request from the facilities to control costs. Facilities sometimes offer incentives for reduced turn time, fuel credits for repositioning the aircraft, free engine shipping or an engine change free of charge (FOC). Many facilities offer these items because they are tangible and easy-to-illustrate savings, but you still need to focus on the out-the-door cost for this event. Have a clear understanding of what the shop has committed to you when you sign the proposal. What I have learned over the years is that the engine overhaul business is not as profitable as one might think. Margins are tight, especially with flat rate labor proposals, so keep that in mind when you ask for incentives — they are not free. The difference has to come out of the profit margin or the facility will try to make up the loss by selling more parts or rework. The facility wants to win your business and will do whatever they can to incentivize you, but understand that the goal is to make their margin target on each job.

Taxes

When you are close to selecting a facility, the critical issues to consider are all the tax implications! Be sure that you understand your tax liability fully. The tax laws are different from state to state and depend on where the work is accomplished, where the engine is delivered, where the aircraft is registered, and the aircraft weight and type of aviation regulation the aircraft operates under. This can add as much as 10 percent to the invoice total. This could affect your facility selection, so don’t commit until you understand how taxes will impact your invoice.

Payment terms are usually standard across the board unless prior arrangements have been made. A deposit is required prior to sending the engine to the shop or before a loaner engine is shipped. The most common terms are 33 to 50 percent down, a second payment after the engine completes inspection with a revised cost estimate, and a final payment after test cell before the engine is released. Make sure there is a clear understanding of the payment terms prior to making your commitment and get it into the agreement.

Now, after careful analysis of all the data listed in your spreadsheet and all the negotiations have concluded, you need to complete the facility selection process and choose a date when the work will occur. The fact that you started the process early should give you preferential choice of time slots. Remember, the proposals are normally effective for only 30 days, so make sure your estimate is still valid prior to signing. Dragging your feet could cost you a preferred time slot. When you have the commitment on dates, sign the proposal as soon as possible and make sure you send it via e-mail or preferred postal. Many forget this step and assume it’s all set up and ready to go. Always follow up with a phone call and e-mail to confirm the dates and that your signed proposal has been received.

In Part Three of this series in the next D.O.M. issue, we will continue this discussion by covering what happens once your aircraft goes into the shop and how to monitor and control the event effectively.

George Kleros is responsible for JSSI’s global technical operations and has more than 28 years of experience in aviation maintenance, management and field support services. He currently serves on GAMA’s airworthiness and maintenance policy committee, is a board member of the Westchester Aircraft Maintenance Association since 2009, and is a PAMA member. He has served as the chairperson for the Trade Technology Board of the Stratford School of Aviation Maintenance. He holds IA and A&P FAA ratings.